Laser Cladding Technology- Optimal Solution – Cost-effective – Prolongs Equipment Lifespan

In steel rolling mills, the mandrel shaft plays a critical role in the coiling and uncoiling process. After prolonged operation, it often suffers from wear, cracks, or surface layer damage due to heavy load, high friction, and continuous work cycles.

Replacing a worn mandrel shaft is costly and leads to production downtime. Laser Cladding Technology offers the optimal solution to restore dimensions, enhance durability, and significantly reduce maintenance costs.

✅ Why Laser Cladding is the Best Solution for Mandrel Shaft Refurbishment

Compared to traditional repair methods such as arc welding, thermal spray, or conventional weld overlay, Laser Cladding stands out with the following advantages:

- No deformation to the shaft: due to minimal heat-affected zone (HAZ), the shaft retains its roundness and alignment.

- Superior coating quality: metallurgical bond ensures strong adhesion between coating and base material, preventing delamination.

- High precision restoration: CNC-controlled cladding guarantees uniform coating thickness and accurate dimensions.

- Excellent resistance to wear, heat, and corrosion: using advanced alloys such as Stellite, Inconel, Tungsten Carbide…

- Extended service life: reduces frequency of repairs and unexpected shutdowns.

In practice, laser cladding has helped steel plants extend the service life of mandrel shafts many times over, reducing maintenance frequency and downtime.

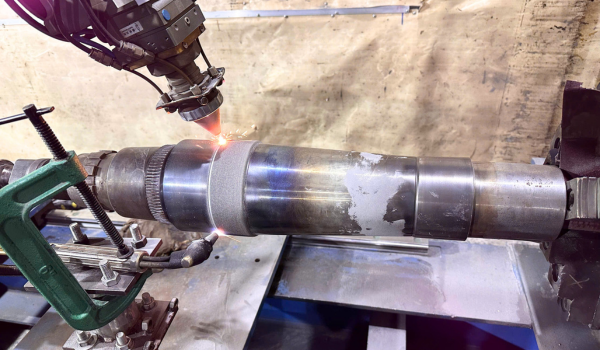

Laser Cladding Process at Phuong Dong

- On-site inspection & wear measurement of the mandrel shaft.

- Material selection based on operating environment (temperature, corrosion, impact…).

- Surface preparation: cleaning and roughening to enhance adhesion.

- Laser Cladding with multi-layer options, CNC controlled for accurate coating thickness.

- Post-cladding machining to restore original specifications.

- Non-Destructive Testing (NDT) to ensure coating quality – free from cracks, porosity, or delamination.

Applications in Steel Plants

Laser Cladding is widely applied to refurbish high-wear components in steel production lines, including:

- Coiler Mandrel Shafts: used at the end of cold rolling lines to coil finished steel sheets.

- Uncoiler Mandrel Shafts: used at the entry of production lines to uncoil raw steel coils.

- Slitter Shafts: for cutting steel into narrow strips.

- Drive and support shafts in rolling mills: continuously exposed to friction and high mechanical load.

- Other surfaces in direct contact with steel coils: prone to scratches, cracks, and surface damage.

Laser Cladding extends the lifespan of these components, reduces replacement costs, and minimizes production downtime.

Before & After Refurbishment

Contact Us for High-Quality Mandrel Shaft Refurbishment

Phuong Dong is a pioneer in Laser Cladding solutions in Vietnam, specializing in refurbishment of heavy-duty industrial equipment for industries such as steel, cement, power generation, and oil & gas. We are committed to:

- Premium coating quality and extended service life

- Fast turnaround and cost-effective solutions

- Experienced engineering team – Modern equipment

Contact Us for Technical Consultation and Service:

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông