Comparison Between Laser Cladding and Other Surface Coating Methods

Surface coating is an effective solution to enhance durability, restore, and extend the lifespan of machine components under harsh working conditions. Today, the most common methods include: Laser Cladding, Plasma Transferred Arc (PTA) welding, Thermal Spray Coating, High-Velocity Oxy-Fuel (HVOF), and traditional welding methods like MIG/MAG. So which technology is the most suitable for your business?

Laser Cladding – The Most Advanced and Precise Technology Today

Laser cladding uses a high-powered laser beam to melt the coating material (in powder or wire form), creating a metallurgical bond between the coating and the base material.

Key Advantages:

- High precision, automated with CNC or robots

- Uniform, strong coatings with no cracks

- Very small heat-affected zone – minimizes part distortion

- Ideal for wear- and impact-resistant parts: shafts, gears, cylinder linings…

Disadvantages:

- High equipment and operational cost

- Requires highly skilled technicians

Plasma Transferred Arc (PTA) Welding

PTA uses a plasma arc and alloy powder to create a durable surface coating.

Advantages:

- Good adhesion and thick coating

- High wear resistance

- Suitable for shafts, valves, and large components

Disadvantages:

- Larger heat-affected zone compared to laser

- May deform thin parts

HVOF

HVOF (High Velocity Oxy-Fuel) is a spraying method using high-speed combustion gas to shoot the coating material onto the surface.

Advantages:

- Extremely hard coating with excellent mechanical adhesion

- Suitable for corrosion- and wear-resistant parts (e.g., pistons, molds, shafts…)

Disadvantages:

- No metallurgical bond (only mechanical adhesion)

- Not suitable for parts under heavy impact loads

- Difficult to apply on complex shapes

Thermal Spray Coating

A traditional technique that sprays molten material onto the surface.

Advantages:

- Fast and can cover large areas

- Minimal effect on base material

Disadvantages:

- Coating may peel off

- Not suitable for dynamic loads and strong impacts

MIG/MAG Welding – Common Traditional Method

Manual arc welding and MIG/MAG methods are easy to implement but not suitable for high technical requirements.

Advantages:

- Low cost

- Widely available equipment

Disadvantages:

- Uneven coating

- Large heat zone, easy to deform the workpiece

- Low coating lifespan

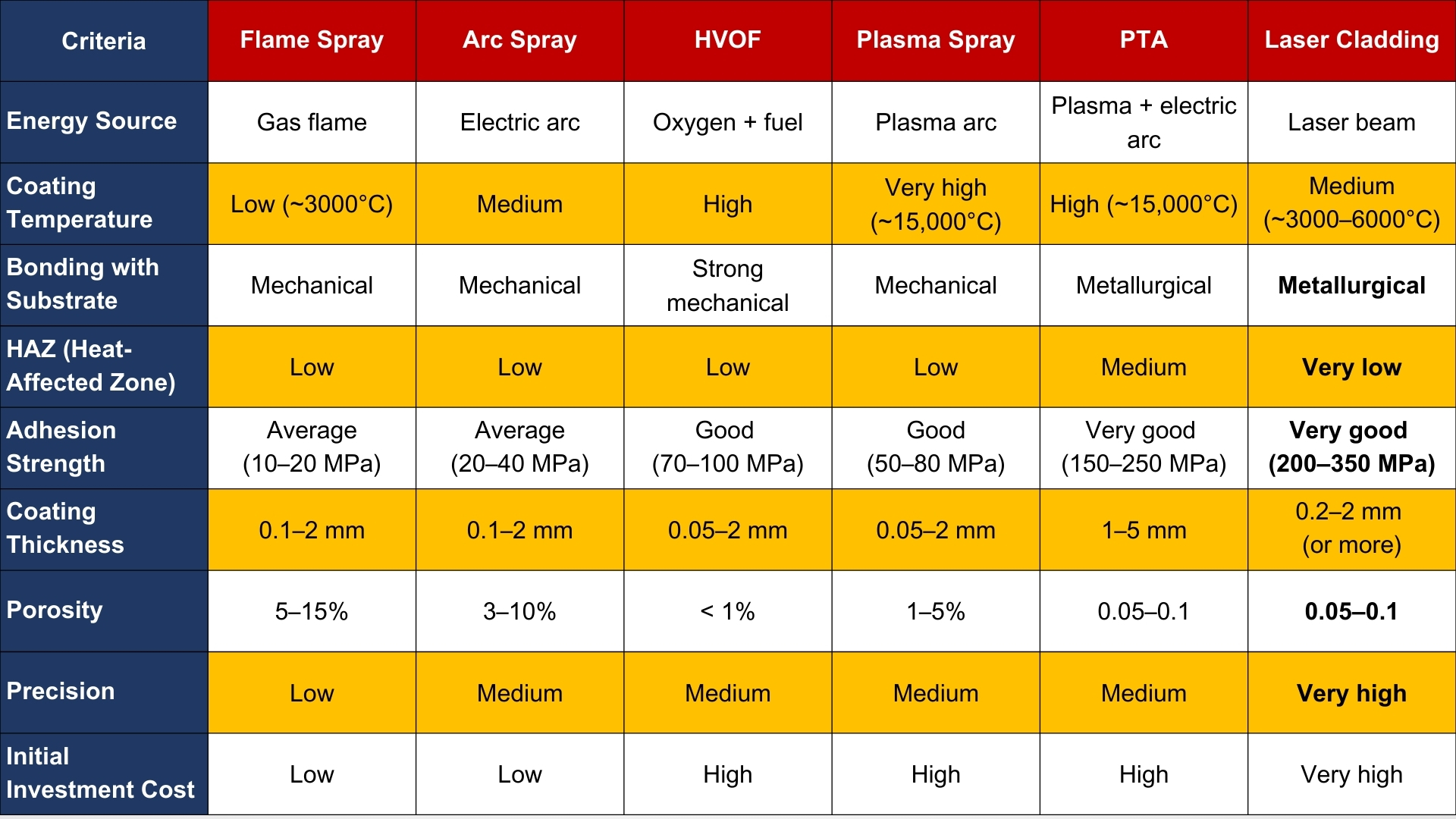

Comparison Table

| Criteria | Laser Cladding | PTA Welding | HVOF | Thermal Spray | MIG/MAG Welding |

| Precision | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Bonding Type | ⭐⭐⭐⭐⭐ (Metallurgical) | ⭐⭐⭐⭐ (Metallurgical) | ⭐⭐ (Mechanical) | ⭐ (Mechanical) | ⭐⭐ |

| Wear Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Impact Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐ | ⭐⭐ |

| Distortion Control | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ |

| Initial Investment Cost | ⭐ | ⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ |

Comparison Table of Surface Coating Methods

Conclusion

If you need to restore or enhance components that face extreme wear, heavy load, and require precision, laser cladding is the most optimal choice. Though the initial cost is high, the long-term efficiency is superior.

Meanwhile, HVOF is ideal for extremely hard coatings, but not suitable for impact-loaded parts. PTA welding is a good intermediate solution, while thermal spray and traditional welding are only recommended for basic applications without high durability requirements.

Consult with PHUONG DONG INDUSTRY

We specialize in laser cladding services, PTA welding, and surface heat treatment, serving industries like cement, steel, mining, oil & gas, and many other heavy industries.

Contact us for consultation and support:

PHUONG DONG TRADING & INDUSTRY CO., LTD

Address: Lane 70, Dan Di Street, Uy No Commune, Dong Anh District, Hanoi, Vietnam

Phone/Zalo: 0987.822.360 – Email: [email protected]

#LaserCladding #SurfaceTreatment #IndustrialWelding #HVOF #ComponentRepair #PhuongDongIndustry

Laser Cladding Phương Đông

Laser Cladding Phương Đông