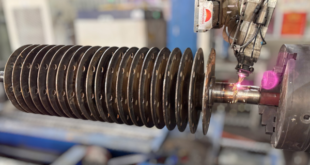

The rotor of a swing hammer crusher is subjected to severe wear and impact during the crushing of hard materials such as stone, clinker, slag, and ore. Over time, the hammer heads, throw arms, and rotor surfaces wear unevenly, leading to decreased crushing efficiency, rotor imbalance, and excessive vibration that ...

Read More »quantri

Hydro Generator Rotor Repair Using Laser Cladding

Why is rotor repair necessary? The rotor is the central rotating component of a hydro generator, operating under heavy load and in harsh conditions. Over time, it often experiences: Surface wear at bearing or journal areas Cracks, pitting, or scratches due to friction and temperature Dimensional deviations affecting dynamic balance ...

Read More »Laser Cladding Repair for Aluminum Piston Heads Using Aluminum Powder

Piston heads made from aluminum alloy are widely used in automotive engines, compressors, and industrial equipment due to their lightweight, high thermal conductivity, and excellent heat resistance. However, during operation, piston heads are prone to wear, cracks, and deformation, which can negatively impact engine performance. PHUONGDONG INDUSTRY offers a high-precision ...

Read More »Laser Cladding for Restoring Inner Bore of Gear Shaft Ø30mm

Laser cladding for inner bore repair of gear shafts (Ø30mm) is an optimal solution to restore worn, cracked, or deformed surfaces caused by industrial operation. At PHUONGDONG INDUSTRY, we apply advanced laser cladding technology to precisely restore the inner bore of gear shafts. The process creates a high-hardness alloy layer ...

Read More »Internal Cylinder Bore Repair Using Laser Cladding Technology

Laser Cladding is increasingly used in the repair and surface enhancement of industrial components. For hollow parts such as cylinder bores, internal surface restoration presents a number of technical challenges due to space limitations and a high risk of thermal distortion, cracking, and coating delamination. Challenges in Internal Surface Cladding ...

Read More »Laser Cladding Repair for Fan Blades – Effective Repair Without Distortion

Fan blades in turbines, compressors, and industrial ventilation systems operate in harsh environments, constantly exposed to high temperatures, dust, and corrosive gases. Over time, this causes significant erosion and corrosion on the blade surface. These components are often thin and delicate, making them highly vulnerable to warping or distortion during ...

Read More »Laser Cladding with Tin-Based Babbitt Powder – The Optimal Solution for Bearing Repair

1. Technology Overview Laser cladding with tin-based Babbitt alloy powder is an advanced surface coating technique that restores worn mechanical components such as journal bearings, bushings, and shaft supports. A high-power laser beam melts the Babbitt powder and fuses it metallurgically with the base material, forming a durable and uniform ...

Read More »Stellite 6 & Stellite 12 Powders for Harsh Environments

Stellite 6 and Stellite 12 are two well-known cobalt-based alloy powders engineered for surface coating applications in demanding working conditions involving high friction, elevated temperatures, chemical corrosion, and cavitation. These powders are ideal for restoration, reinforcement, and extending service life of mechanical components in industries such as oil & gas, ...

Read More »Inconel 625 & Inconel 718 Powders– Advanced Solutions for Extreme Environments

Inconel 625 and Inconel 718 are high-performance nickel-based superalloy powders, specifically designed for surface cladding, strengthening, and component repair in harsh working conditions involving high temperatures, corrosive environments, and heavy mechanical loads. Thanks to their outstanding resistance to oxidation, corrosion, and wear, these materials are ideal for demanding industries such ...

Read More »316L Stainless Steel Powder – An Effective Corrosion-Resistant Solution

What is 316L Stainless Steel Powder? 316L stainless steel is a low-carbon austenitic stainless steel powder, primarily composed of: Chromium (Cr):00 – 18.00% Nickel (Ni):00 – 14.00% Molybdenum (Mo):00 – 3.00% Thanks to this composition, 316L powder offers excellent corrosion resistance, especially in chloride-containing environments such as seawater, steam, mild ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông