Harsh Operating Conditions Faced by Pump Pressure Plates The pressure plate inside a pump housing is a critical component that directly withstands high pressure, heavy friction, and exposure to acidic or chemically corrosive fluids.After long periods of operation, this surface often becomes severely worn or deeply pitted, leading to leakage, ...

Read More »Steel Industry

Laser Cladding Restoration for Pump Housings – A Durable Solution for Harsh Operating Environments

Challenges in Pump Housing Operation Pump housings are critical components in industrial pump systems, constantly exposed to high pressure, heavy friction, and harsh operating environments such as acidic or chemically corrosive fluids.In severe acid or high-corrosion applications, the inner surfaces of the pump housing often suffer scratches, wear, deep pitting, ...

Read More »Laser Cladding Restoration for Pump Shafts

Operating Conditions and Wear Problems in Pump Shafts Pump shafts operate under high torsional loads and are constantly exposed to friction and corrosive environments. Over time, the shaft surface can become worn, scratched, or pitted—directly affecting concentricity, sealing performance, and the overall lifespan of the pump system. Laser Cladding – ...

Read More »Laser Cladding Restoration for Large Closed Impellers

Operating Challenges and Wear Problems in Closed Impellers Closed impellers operate under high pressure and high flow velocity, frequently subjected to severe mechanical wear and cavitation—especially along the outer rim and discharge areas… Closed impellers operate under high pressure and high flow velocity, frequently subjected to severe mechanical wear and ...

Read More »Crankshaft Restoration for Stamping Press Machines Using Laser Cladding Technology

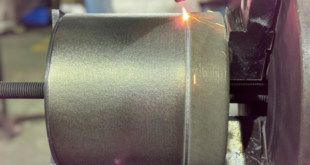

In industrial stamping press systems, the crankshaft plays a central role — converting the motor’s rotational motion into the up-and-down linear motion of the punch. This enables the press to perform accurate and continuous stamping operations during production. Importance of the Crankshaft The crankshaft endures heavy impact loads, repeating millions ...

Read More »Laser Cladding Repair for Coupling Bore – Automatic Laser On/Off at Keyway

In power transmission systems, the coupling is a critical component that connects two shafts and transmits torque. After long periods of operation, the inner surface of the coupling bore often becomes worn, causing vibration and reduced efficiency. At PHUONG DONG, we apply Laser Cladding technology to restore the inner bore ...

Read More »Restoration of Journal Bearing Using Laser Cladding Technology

What is a Journal Bearing? A journal bearing (also known as a sleeve bearing) is a critical mechanical component used to support and guide rotating shafts in industrial machinery. Over time, the bearing surface is prone to wear, scratches, or cracks due to heavy loads, high rotational speeds, and harsh ...

Read More »Bearing Housing Restoration Using Laser Cladding Technology

During operation, bearing housings are often subjected to heavy loads and friction, leading to wear, pitting, cracking, or deformation. These issues reduce service life and negatively impact the overall performance of industrial equipment. At PHUONGDONG INDUSTRY, we apply advanced Laser Cladding technology to restore bearing housings with exceptional precision and ...

Read More »Shaft Restoration with Copper Alloy Powder – Laser Cladding Technology

At PHUONG DONG, we are pioneers in applying advanced Laser Cladding technology to restore shafts and other critical machine components using specialized copper alloy powder. This provides an optimal solution for industries such as precision engineering, oil & gas, chemical processing, marine, and many other industrial sectors. Challenges of Copper ...

Read More »Flange Restoration with Laser Cladding Technology

Laser Cladding Technology – A Modern Repair Solution Laser Cladding is an advanced process that uses a high-power laser beam to melt a thin layer of alloy powder together with the base surface, creating a strong metallurgical bond. At PHUONG DONG, we apply a state-of-the-art 5-axis CNC Laser Cladding system ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông