In sheet metal processing, stamping dies, punching dies, forming dies and bending dies operate under heavy loads, continuous impact and high friction. Without proper heat treatment, these tools wear quickly, suffer from edge chipping, deformation and a rapid reduction in service life. Laser Hardening (Laser heat treatment) is an advanced ...

Read More »Hardening

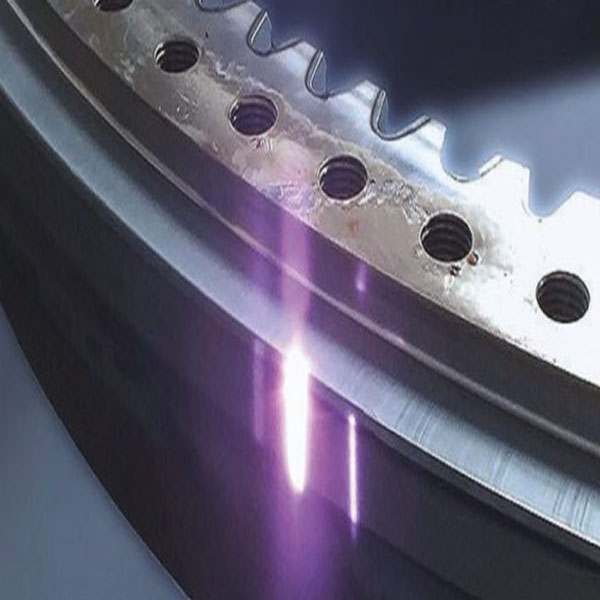

Laser Heat Treatment for Gears – Advanced Technology, Superior Performance

Why do gears need surface hardening?Gears are essential components in power transmission systems. They operate under heavy loads and constant friction and impact. Over time, gear teeth surfaces may wear, crack, or deform.Increasing surface hardness enhances wear resistance, maintains transmission accuracy, improves load capacity, and extends the service life of ...

Read More »Laser Hardening for Plastic Injection Molds

Why Do Injection Molds Need Surface Hardening? During the molding process, molds operate continuously under high pressure, friction, and thermal cycling. Critical areas such as cavity surfaces, edges, ribs, and pins are directly exposed to molten plastic and clamping forces, causing wear, deformation, and loss of dimensional accuracy over time.Therefore, ...

Read More »Laser Hardening for Slide Bars – The Leading Surface Hardening Solution Today

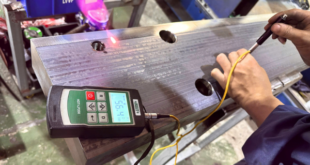

1. Laser Hardening – The Most Advanced Heat Treatment Solution Today Laser Hardening is currently the most advanced surface heat treatment technology. It uses a highly controlled laser beam to heat specific areas on a component’s surface with exceptional precision. This technology is especially ideal for parts that require high ...

Read More »What is Laser Heat Treatment (Laser Hardening)? Applications in Modern Engineering

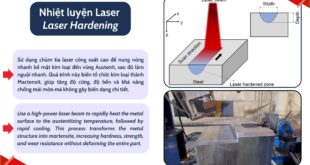

Laser heat treatment, also known as laser hardening, is an advanced surface treatment technology that uses a high-power laser beam to locally heat the surface of metal materials to hardening temperature. Thanks to the extremely rapid self-quenching ability of the base material, the surface layer becomes hardened without altering the ...

Read More »Laser Hardening – Technology Overview & Technical Documentation

Laser hardening is an advanced surface heat treatment technology that uses a high-power laser beam to selectively heat the surface of metal components to their transformation temperature. The material then self-quenches using its own mass, forming a martensitic hardened layer without the need for oil or water cooling. This method ...

Read More »Laser Hardening Technology – A Precise and Modern Surface Hardening Solution

Laser Hardening is an advanced heat treatment technology that uses a high-power laser beam to locally heat the surface of a metal component to its hardening temperature, followed by self-quenching using the material’s own mass. This process creates a high-hardness surface layer, significantly improving wear resistance while avoiding distortion or ...

Read More »Laser Hardening for Crusher Shaft 2m

Laser hardening is a heat treating process used to improve the strength and durability of component surfaces. It employs the use of high-powered diode lasers that apply energy to heat localized areas of the component surface. * Advantages: minimizing warping, fast processing speed, flexibility with different material surfaces. * Application: ...

Read More »Laser Hardening for Roller

Related posts: Laser Hardening for Crusher Shaft 2m Gear Quenching mold

Read More »Gear

Currently, to increase productivity, some countries have applied laser heat treatment technology to heat treatment of gears and camshafts. Compared with traditional heat treatment methods, laser heat treatment has the following advantages: – Enhanced hardness, strength, fatigue and wear resistance properties – Achieve higher accuracy, lower energy requirements, thus reducing ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông