Overview of Laser Cladding Services in Vietnam Laser Cladding services in Vietnam are increasingly being adopted by industrial companies for restoring and extending the service life of metal components. Laser Cladding technology allows the formation of high-strength alloy coatings with excellent wear resistance and corrosion resistance, helping equipment operate reliably ...

Read More »Auto Industry

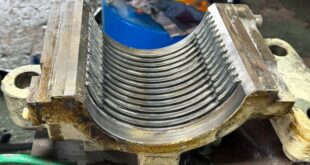

Gear Restoration by Laser Cladding Technology

In the mechanical manufacturing and industrial maintenance industry, gears are critical transmission components operating under heavy loads, high friction, and continuous impact. After long-term operation, gears often suffer from damages such as tooth wear, chipping, broken teeth, surface pitting, or worn bore holes, which reduce transmission accuracy and seriously affect ...

Read More »Inner Bore Restoration by Laser Cladding Technology

Inner bore laser cladding is a technically demanding process that requires specialized equipment and extensive experience, as it involves handling various bore diameters, different depths, and complex component geometries. With conventional welding methods, controlling the quality of the cladding layer inside bores is often limited and difficult to achieve consistently. ...

Read More »Aluminum Piston Refurbishment Using Laser Cladding Technology

Aluminum pistons are critical components in engines, operating under high temperatures, continuous friction, and cyclic mechanical loads. Over time, pistons may suffer from surface wear, deep scratches, crown damage, or dimensional deviation, leading to reduced performance and increased maintenance costs. Laser Cladding – A Precision Refurbishment Solution for Aluminum Pistons ...

Read More »Thread Restoration by Laser Cladding – A Reliable Solution for Industrial Applications

Thread Wear in Industrial Components Threaded sections in industrial machinery often operate under high load, vibration, friction, and exposure to harsh environments. Over long-term operation, threads are prone to wear, deformation, and dimensional loss, leading to loose fittings, reduced tightening ability, and potential operational failures. Traditional repair or replacement methods ...

Read More »Crankshaft Restoration for Stamping Press Machines Using Laser Cladding Technology

In industrial stamping press systems, the crankshaft plays a central role — converting the motor’s rotational motion into the up-and-down linear motion of the punch. This enables the press to perform accurate and continuous stamping operations during production. Importance of the Crankshaft The crankshaft endures heavy impact loads, repeating millions ...

Read More »Laser Cladding Repair for Coupling Bore – Automatic Laser On/Off at Keyway

In power transmission systems, the coupling is a critical component that connects two shafts and transmits torque. After long periods of operation, the inner surface of the coupling bore often becomes worn, causing vibration and reduced efficiency. At PHUONG DONG, we apply Laser Cladding technology to restore the inner bore ...

Read More »Broken Gear Tooth Restoration with Laser Cladding Technology

Broken or chipped teeth on large gears due to overload during operation is a common failure in heavy industries such as cement, steel, and mining. At Phuong Dong Industry, we apply Laser Cladding technology to restore damaged gears, offering a cost-effective and sustainable alternative to complete replacement. Outstanding Advantages of ...

Read More »Advanced Laser Cladding Technology for Ø70 Small Bore Surfaces

Repairing small bores such as Ø70 is one of the most technically demanding challenges in precision mechanical restoration. With a narrow diameter and limited space, the process requires extremely high accuracy, along with precise control of the heat input and cladding thickness to ensure strong bonding and coating quality. Challenges ...

Read More »Laser Cladding Repair for Piston Rods

Laser Cladding is an advanced surface restoration and strengthening technology. It utilizes a high-energy, focused laser beam to melt metallic powder and fuse it with the base material surface. This process creates a dense, wear-resistant coating with excellent bonding and mechanical properties. Laser cladding is especially suitable for components subject ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông