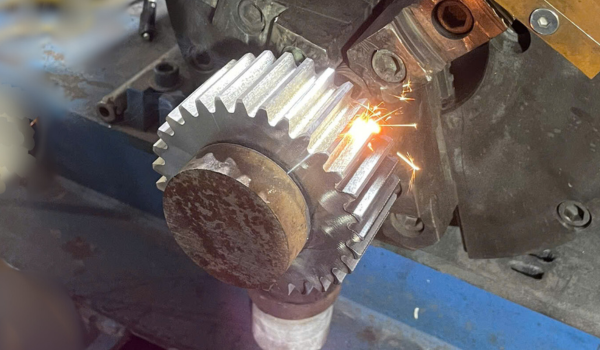

Why do gears need surface hardening?

Gears are essential components in power transmission systems. They operate under heavy loads and constant friction and impact. Over time, gear teeth surfaces may wear, crack, or deform.

Increasing surface hardness enhances wear resistance, maintains transmission accuracy, improves load capacity, and extends the service life of the equipment.

Why choose Laser Heat Treatment?

Compared to traditional heat treatment methods, Laser Hardening offers significant advantages:

- High precision: Only the gear teeth surfaces are treated.

- Low deformation: Concentrated heat minimizes distortion.

- High speed: Localized treatment in a short time.

- Cost efficiency: Reduced maintenance costs and machine downtime.

Advantages over conventional methods

✅ High surface hardness (50–60 HRC).

✅ Small heat-affected zone → minimal warping.

✅ No quenching medium required – self-cooling in air.

✅ Longer gear lifespan, reduced replacement costs.

With advanced Laser Heat Treatment technology, PHUONG DONG INDUSTRY helps businesses enhance gear quality, ensuring durable, precise, and cost-effective performance of power transmission systems.

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông