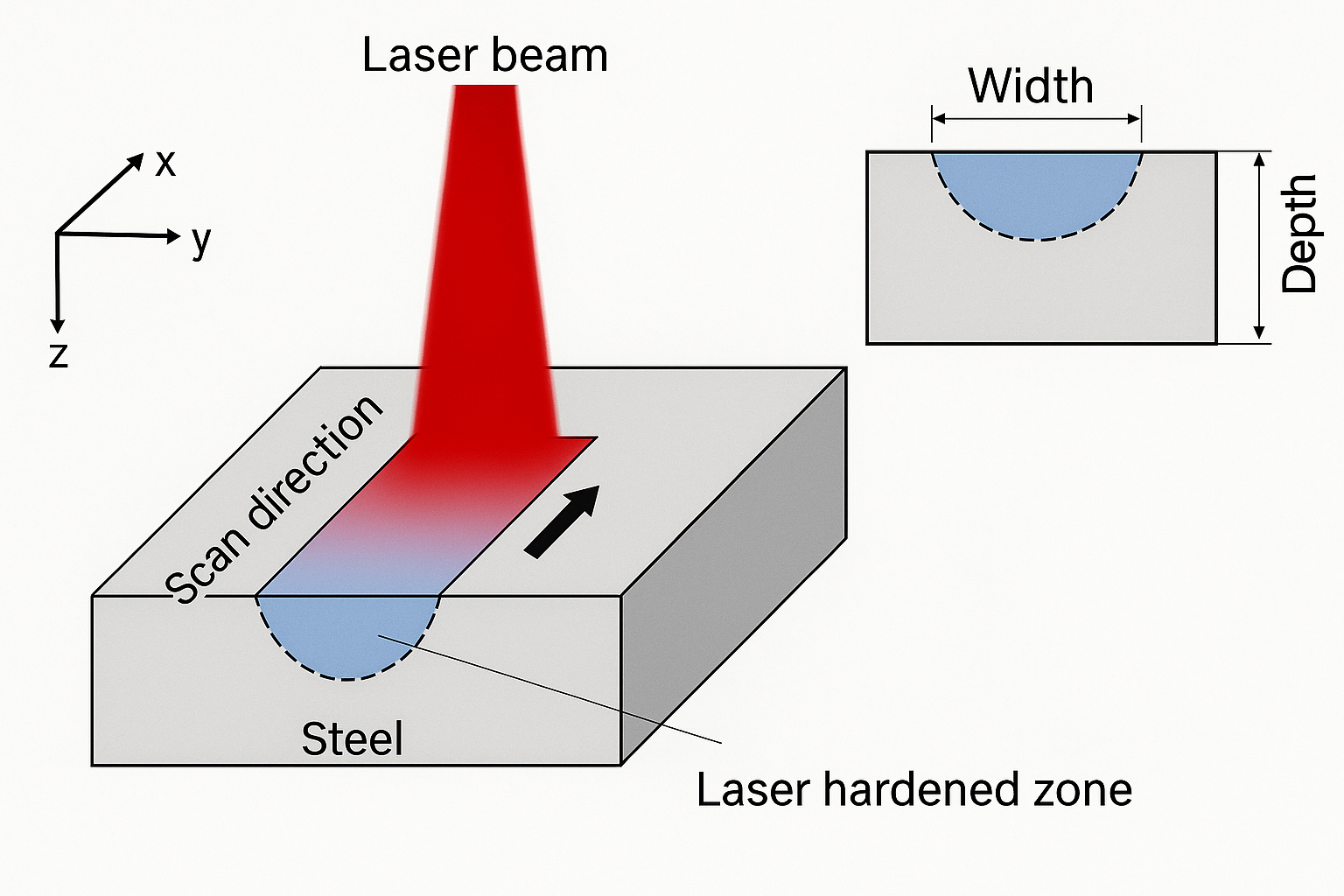

Laser hardening is an advanced surface heat treatment technology that uses a high-power laser beam to selectively heat the surface of metal components to their transformation temperature. The material then self-quenches using its own mass, forming a martensitic hardened layer without the need for oil or water cooling.

This method offers high hardness (typically 50–65 HRC), outstanding wear resistance, and minimal distortion—making it ideal for precision components that require long-term durability.

Key Benefits of Laser Hardening

- High precision: Controlled depth and targeted hardening area.

- No deformation: No quenching media, no part warping.

- Eco-friendly: No fumes, no chemicals, and clean processing.

- Efficient: No need for post-treatment (tempering), reducing processing time.

- Automation ready: Easily integrated into CNC or robotic systems.

Applications

- Components subjected to high wear: gears, shafts, molds, cams, rollers, rails, etc.

- Industries: automotive, steel, tooling, mold-making, heavy equipment manufacturing.

Download Detailed Technical Document

For engineers, partners, and clients seeking deeper insight into the laser hardening process, we provide a comprehensive document including:

✅ Working principles

✅ Step-by-step process

✅ Key technical parameters

✅ Real-world applications and diagrams

✅ Comparison with traditional hardening methods

Click here to view/download the full document: Laser Hardening (2025)

Contact us for consultation and support:

PHUONG DONG TRADING & INDUSTRY CO., LTD

Address: Lane 70, Dan Di Street, Uy No Commune, Dong Anh District, Hanoi, Vietnam

Phone/Zalo: 0987.822.360 – Email: [email protected]

Laser Cladding Phương Đông

Laser Cladding Phương Đông