1. Laser Hardening – The Most Advanced Heat Treatment Solution Today

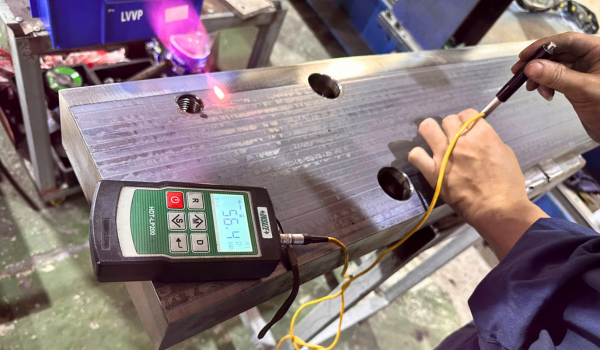

Laser Hardening is currently the most advanced surface heat treatment technology. It uses a highly controlled laser beam to heat specific areas on a component’s surface with exceptional precision. This technology is especially ideal for parts that require high surface hardness, complex shapes, and absolute dimensional accuracy – such as slide bars in linear motion systems.

2. Why Choose Laser Hardening for Slide Bars?

Slide bars often operate under high friction, continuous motion, and harsh industrial environments. Enhancing the surface hardness is a key factor in extending lifespan and maintaining operational performance.

3. Outstanding Advantages of Laser Hardening

✅ Surface hardness up to HRC 50–60

✅ Minimal distortion, no need for post-machining

✅ Precise heating on target areas

✅ No impact on the core of the part

✅ Enhanced wear resistance and load capacity

✅ Suitable for complex geometries

4. Real-World Applications

Laser hardening for slide bars is widely used in:

- CNC machines, cutting machines, grinding machines

- Industrial robots and automation systems

- Linear drive systems

- Presses, stamping machines, and mold production lines

5. Versatile Applications Across Industries

- Precision Engineering

- Automotive & Motorcycles

- Mold Manufacturing

- Machine Building

- Industrial Automation

6. What Sets Us Apart?

At PHUONGDONG INDUSTRY, we don’t just offer laser hardening – we deliver precision, performance, and reliability:

- Capable of processing small, medium, and large components

- Guaranteed high quality, precision, and durability

- Operated by experienced technicians with modern equipment

Contact Us for Technical Consultation and Service:

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông