Why Do Injection Molds Need Surface Hardening?

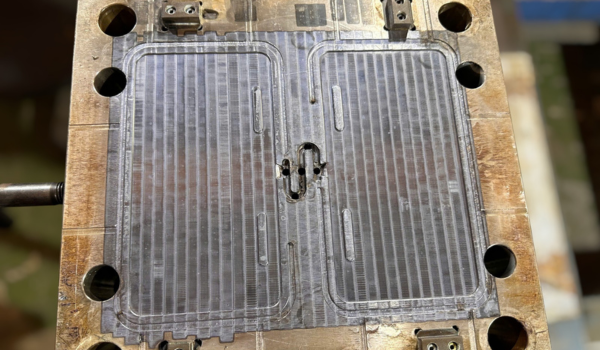

During the molding process, molds operate continuously under high pressure, friction, and thermal cycling. Critical areas such as cavity surfaces, edges, ribs, and pins are directly exposed to molten plastic and clamping forces, causing wear, deformation, and loss of dimensional accuracy over time.

Therefore, increasing the surface hardness is essential to maintain precision, extend mold life, and reduce maintenance costs.

Principle of Laser Hardening

Laser Hardening technology uses a concentrated laser beam to heat specific areas of the mold surface to a temperature above the critical point.

- The surface heats up extremely fast, transforming its microstructure.

- Upon self-cooling in air, the heated zone converts to martensite, a hard and wear-resistant structure.

- The core remains unaffected, preserving the original toughness and strength.

As a result, the mold achieves a high surface hardness (45–60 HRC) without the need for overall heating or quenching.

Why Choose Laser Hardening?

Compared to conventional heat treatment methods, Laser Hardening offers remarkable advantages:

- High Precision: Only the required areas are treated, without affecting the entire part.

- No Deformation: Minimal heat-affected zone ensures original geometry and accuracy.

- Eco-Friendly & Cost-Effective: No need for quenching media, reducing energy and auxiliary costs.

- Fast Processing: Localized treatment enables short cycle times, ideal for industrial applications.

Benefits

- Surface hardness up to 45–60 HRC

- No distortion or warping

- Air self-cooling – no quenching required

- Extended mold life, reduced repair and replacement costs

With advanced Laser Hardening technology, PHUONGDONG INDUSTRY helps manufacturers enhance mold quality, ensuring durability, precision, and cost efficiency in production.

Contact Us for Technical Consultation and Service:

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông