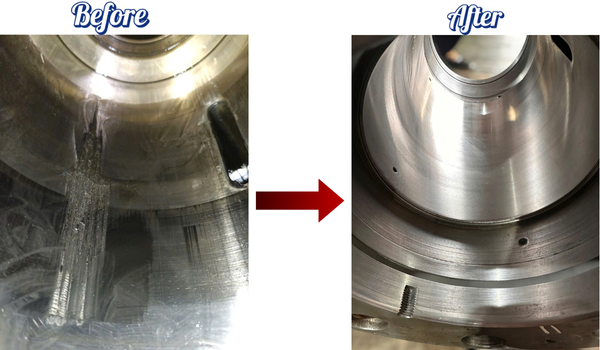

Laser Cladding is increasingly used in the repair and surface enhancement of industrial components. For hollow parts such as cylinder bores, internal surface restoration presents a number of technical challenges due to space limitations and a high risk of thermal distortion, cracking, and coating delamination.

Challenges in Internal Surface Cladding

- Thermal shrinkage during and after cladding can create significant residual stress.

- Geometric distortion affects concentricity and dimensional accuracy.

- Poor bonding may lead to delamination of the cladding layer.

- Tight inner space requires specialized equipment to access and operate precisely.

Our Technological Solution

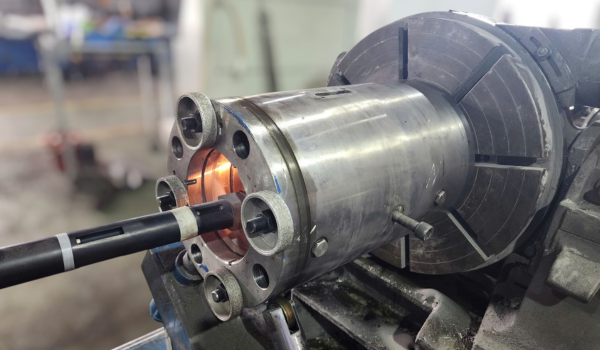

At Phuong Dong Industry, we use a rotating internal laser cladding system with the following advantages:

- Accurate heat input control, reducing residual stress and shrinkage.

- Specially designed rotating cladding heads that can operate inside various bore diameters.

- Use of high-performance cladding powders (e.g., Ni-based, Co-based, or wear-resistant alloys), tailored to each application.

- Automated system ensures uniform layer thickness and strong metallurgical bonding.

Common Applications

- Hydraulic and pneumatic cylinders

- Large engine cylinder bores (diesel, turbine, etc.)

- Industrial piping subject to wear

- Liners used in steel, cement, and mining industries

Key Benefits

✅ Extends service life of original components

✅ Cost-effective alternative to replacement

✅ Reduces downtime

✅ Restores original design specifications with high precision

Looking for a durable and high-quality solution for internal cylinder bore restoration?

Contact us for tailored laser cladding services that meet your technical needs.

PHUONG DONG TRADING AND INDUSTRY CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông