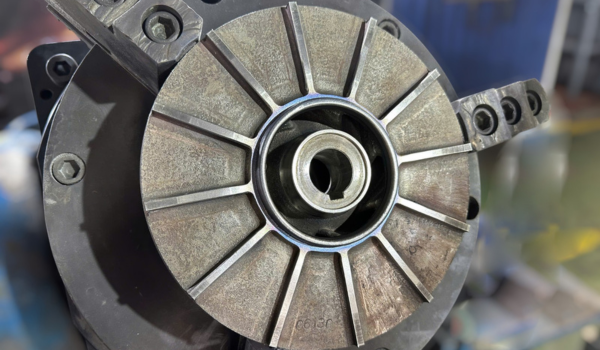

In industrial pump systems—especially in hydroelectric, thermal power, and oil & gas plants—the impeller plays a vital role in maintaining stable operation and high performance. During long-term use, impellers are exposed to abrasive particles, chemical corrosion, and cavitation, leading to surface wear, pitting, or cracking. These damages reduce pump efficiency, cause energy loss, and may even result in unexpected shutdowns.

In the past, the common solution was to replace the entire impeller, which was costly and time-consuming. Today, thanks to Laser Cladding technology, impeller restoration has become a faster, more precise, and cost-effective alternative.

Advantages of Laser Cladding for Impeller Restoration

- Extended Service Life: The alloy-clad surface provides superior wear and corrosion resistance.

- Cost Efficiency: Restoring impellers instead of replacing them significantly reduces expenses.

- High Precision: The process is CNC-controlled for consistent, accurate material deposition.

- Original Geometry Retained: Minimal heat input ensures no distortion or structural change.

- Stable Quality: The process is managed under ISO 9001:2015 standards, ensuring reliability even in harsh operating environments.

Laser Cladding Restoration Process

- Inspection & Assessment: Evaluate the damage level of the impeller.

- Surface Preparation: Clean and machine the worn areas before cladding.

- Laser Cladding: Apply suitable alloy powder according to working conditions (anti-wear, corrosion-resistant, or heat-resistant).

- Post-Cladding Processing: Machining, grinding, and finishing to restore original dimensions.

- Quality Control: Perform hardness testing, ultrasonic inspection, and surface examination to ensure conformity to standards.

By applying this solution, industries can restore and reuse impellers multiple times instead of costly replacements—demonstrating the superior efficiency and sustainability of Laser Cladding technology in modern manufacturing and maintenance.

Contact Us for Technical Consultation and Service:

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông