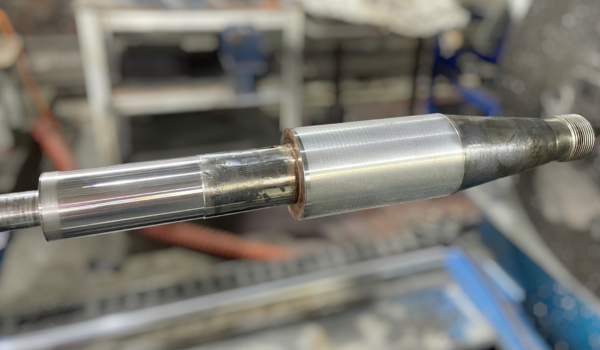

During operation, grinding machine shafts often experience wear, cracks, or deformation caused by friction and heavy loads. Laser Cladding is a modern restoration solution that rebuilds the original geometry, strengthens the surface, and extends equipment lifespan.

Advantages of Laser Cladding Technology

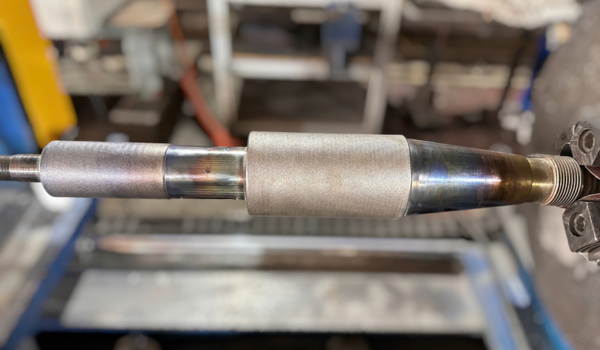

- High Precision: The coating layer is applied accurately and uniformly to the worn area.

- Superior Quality: The clad layer adheres strongly, providing excellent wear and corrosion resistance.

- Minimal Thermal Deformation: The workpiece remains stable with no warping or distortion.

- Extended Equipment Life: Reduces maintenance costs and minimizes downtime.

Restoration Process at PHUONGDONG INDUSTRY

- Damage assessment of the grinding machine shaft.

- Selection of suitable alloy powder for restoration.

- Laser cladding process.

- Machining and finishing to restore standard dimensions.

- Quality inspection before delivery.

Images: Grinding Machine Shaft Before and After Laser Cladding

Why Choose PHUONGDONG INDUSTRY?

- Advanced Technology: Equipped with state-of-the-art Laser Cladding systems.

- ISO 9001:2015 Certified: Ensures consistent quality that meets international standards.

- Experienced Team: Skilled engineers with extensive experience in complex restoration projects.

- High-Quality Materials: Uses internationally certified alloy powders.

- Cost and Time Efficiency: Minimizes machine downtime and optimizes operational performance.

PHUONGDONG INDUSTRY – Your Trusted Partner in Machine Part Restoration Using Laser Cladding Technology.

Contact Us for Technical Consultation and Service:

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông