In the manufacturing and mechanical industries, machine parts operate under high loads, friction, and harsh environments. Over time, these conditions lead to wear, corrosion, cracking, and dimensional deformation. Instead of replacing these parts—which can be expensive and time-consuming—Laser Cladding has become a smart, modern solution for restoring and extending part life.

Below are the 5 most common types of damage to mechanical parts and how Laser Cladding effectively restores them:

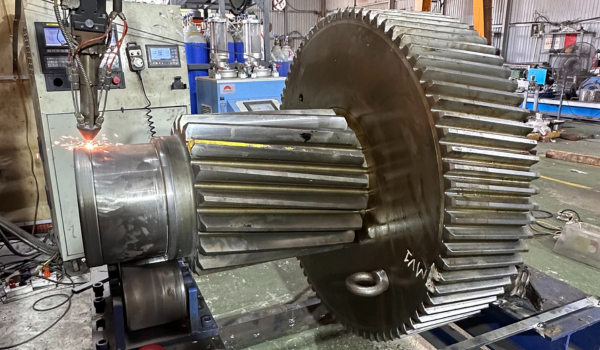

1. Surface Wear

Cause:

Occurs due to constant friction between moving parts such as shafts, gears, and bearings. This leads to loss of material, reduced accuracy, and increased clearance.

Laser Cladding Solution:

Laser Cladding allows the deposition of a wear-resistant layer (e.g. cobalt, nickel alloys, tungsten carbide) directly on the worn surface. This restores the original geometry and significantly improves wear resistance.

2. Chemical Corrosion

Cause:

Exposed parts to aggressive environments (e.g. acids, seawater) suffer from pitting, rusting, and surface degradation.

Laser Cladding Solution:

By cladding corrosion-resistant alloys (like Inconel, stainless steel), the surface becomes highly resistant to oxidation and chemicals, extending the service life of parts in harsh environments.

3. Stress Cracking

Cause:

Mechanical parts under cyclic loads or high thermal shock may develop microcracks that can spread and cause failure.

Laser Cladding Solution:

Cracked zones are removed and replaced with a new clad layer that is metallurgically bonded to the base metal, increasing strength and reducing susceptibility to cracking.

4. Deformation and Loss of Tolerance

Cause:

Parts may warp, bend, or go out of tolerance after prolonged use or due to thermal-mechanical stress.

Laser Cladding Solution:

After machining out the deformed areas, Laser Cladding rebuilds the material precisely, restoring dimensional accuracy without affecting base metal properties.

5. Expensive, Hard-to-Replace Parts

Cause:

Certain components are custom-made, imported, or require long manufacturing times. When damaged, replacing them is costly and causes downtime.

Laser Cladding Solution:

Laser Cladding restores these valuable parts quickly and economically, minimizing machine downtime and avoiding full replacement.

Why Choose Laser Cladding?

- High precision & minimal distortion

- Stronger bond than traditional welding or spraying

- Material-saving and cost-effective

- Applicable for both new and worn parts

If your business is looking to restore damaged mechanical components instead of replacing them, Laser Cladding is a high-tech, reliable solution that helps reduce cost, downtime, and extend the life of your equipment.

Contact us for consultation and support:

PHUONG DONG TRADING AND INDUSTRY CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo: 0987.822.360

Laser Cladding Phương Đông

Laser Cladding Phương Đông