Shaft rejoining is one of the most challenging mechanical repair techniques, requiring high precision and strict thermal control. Industrial shafts operate under heavy loads, continuous friction, and strong vibration; once a shaft breaks, it is often discarded and replaced—leading to high costs and production downtime. Traditional welding methods rarely achieve ...

Read More »quantri

Restoring D90 Bearing Holes on Gearbox Housings Using Laser Cladding Technology

During long-term operation, the bearing holes in gearbox housings often experience wear or deformation, causing misalignment and seriously affecting the transmission system. For large gearbox housings, the repair of small holes (D90) located deep inside presents challenges for both welding operations and fixture setup. Challenges of the D90 Hole Location ...

Read More »Grinding Robots – A Solution to Replace Manual Labor in Heavy Industries

In modern manufacturing plants, grinding and surface finishing tasks often require significant time and rely heavily on manual labor, leading to low productivity and inconsistent quality. Robotic grinding technology offers an effective solution by automating the process, enhancing accuracy, and ensuring consistent results across all workpieces. 1. What is a ...

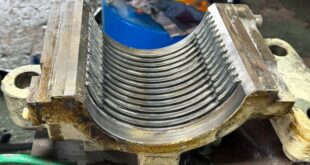

Read More »Thread Restoration by Laser Cladding – A Reliable Solution for Industrial Applications

Thread Wear in Industrial Components Threaded sections in industrial machinery often operate under high load, vibration, friction, and exposure to harsh environments. Over long-term operation, threads are prone to wear, deformation, and dimensional loss, leading to loose fittings, reduced tightening ability, and potential operational failures. Traditional repair or replacement methods ...

Read More »Laser Cladding Restoration for Pump Pressure Plates – A Reliable Solution for Harsh Operating Environments

Harsh Operating Conditions Faced by Pump Pressure Plates The pressure plate inside a pump housing is a critical component that directly withstands high pressure, heavy friction, and exposure to acidic or chemically corrosive fluids.After long periods of operation, this surface often becomes severely worn or deeply pitted, leading to leakage, ...

Read More »Laser Cladding Restoration for Pump Housings – A Durable Solution for Harsh Operating Environments

Challenges in Pump Housing Operation Pump housings are critical components in industrial pump systems, constantly exposed to high pressure, heavy friction, and harsh operating environments such as acidic or chemically corrosive fluids.In severe acid or high-corrosion applications, the inner surfaces of the pump housing often suffer scratches, wear, deep pitting, ...

Read More »Laser Cladding Restoration for Pump Shafts

Operating Conditions and Wear Problems in Pump Shafts Pump shafts operate under high torsional loads and are constantly exposed to friction and corrosive environments. Over time, the shaft surface can become worn, scratched, or pitted—directly affecting concentricity, sealing performance, and the overall lifespan of the pump system. Laser Cladding – ...

Read More »Laser Cladding Restoration for Large Closed Impellers

Operating Challenges and Wear Problems in Closed Impellers Closed impellers operate under high pressure and high flow velocity, frequently subjected to severe mechanical wear and cavitation—especially along the outer rim and discharge areas… Closed impellers operate under high pressure and high flow velocity, frequently subjected to severe mechanical wear and ...

Read More »Restoration of Deeply Worn Generator Shaft Using Laser Cladding – The Most Advanced Solution

Generator Shaft Journal and Wear Condition The shaft journal is a critical component in a generator, responsible for centering and transmitting the rotational motion between the rotor and its connected parts. During continuous operation, it is subjected to high loads, friction, vibration, and elevated temperatures, leading to surface wear, erosion, ...

Read More »Crankshaft Restoration for Stamping Press Machines Using Laser Cladding Technology

In industrial stamping press systems, the crankshaft plays a central role — converting the motor’s rotational motion into the up-and-down linear motion of the punch. This enables the press to perform accurate and continuous stamping operations during production. Importance of the Crankshaft The crankshaft endures heavy impact loads, repeating millions ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông