Laser Cladding for Babbitt bearings is an advanced restoration method widely used for sliding bearings in industrial equipment such as turbines, fans, pumps, and engines. Laser Cladding technology uses a high-power laser beam to melt Babbitt alloy powder and create a strong metallurgical bond with the base material, producing a ...

Read More »quantri

Why Is Cast Iron Difficult to Weld? Can Laser Cladding Repair Cast Iron?

Cast iron is widely used in industry to manufacture machine bodies, pump housings, shafts, and wear-resistant components. However, when cast iron parts crack or wear out, repair is often more difficult than for steel. In practice, welding cast iron is considered one of the most challenging tasks in mechanical repair. ...

Read More »Laser Cladding Technology in Vietnam – Current Status and Development Trends

Laser Cladding technology in Vietnam is receiving increasing attention and is being widely applied in mechanical engineering and heavy industries. This advanced surface engineering technology uses a high-power laser beam to create a durable alloy layer on metal surfaces, improving wear resistance, corrosion resistance, and extending component service life. In ...

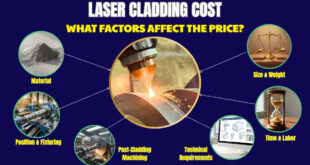

Read More »What Factors Affect Laser Cladding Cost?

The cost of Laser Cladding services can vary depending on the type of component, cladding material, and technical requirements. Unlike many conventional repair methods, Laser Cladding cost is usually calculated based on multiple technical factors rather than a fixed price. Understanding the factors that affect Laser Cladding cost helps companies ...

Read More »When Should You Choose Laser Cladding Instead of Replacement?

During industrial operation, many mechanical components wear out or become damaged over time. In such cases, companies must decide between Laser Cladding repair and manufacturing a new part. In many situations, Laser Cladding is a more economical and efficient solution than full replacement. Laser Cladding restores the original dimensions of ...

Read More »Laser Cladding Services in Vietnam

Overview of Laser Cladding Services in Vietnam Laser Cladding services in Vietnam are increasingly being adopted by industrial companies for restoring and extending the service life of metal components. Laser Cladding technology allows the formation of high-strength alloy coatings with excellent wear resistance and corrosion resistance, helping equipment operate reliably ...

Read More »Industrial Fan Shaft Repair by Laser Cladding at Phuong Dong

During long-term operation, industrial fan shafts are often subjected to wear, scratches, surface pitting or dimensional deviation due to friction, heavy loads and harsh working conditions. If not treated in time, these defects may cause vibration, reduced efficiency and even serious damage to the entire equipment system. Replacing a new ...

Read More »Repair of D110 Bearing Bore in Compressor Housing by Laser Cladding

In industrial manufacturing and equipment maintenance, the bearing bore in compressor housing is a critical position, subjected to heavy loads and requiring high accuracy and concentricity. After long-term operation, this area is often worn oversized, scratched or pitted, causing vibration and quickly leading to damage of the bearing, shaft and the ...

Read More »Gear Restoration by Laser Cladding Technology

In the mechanical manufacturing and industrial maintenance industry, gears are critical transmission components operating under heavy loads, high friction, and continuous impact. After long-term operation, gears often suffer from damages such as tooth wear, chipping, broken teeth, surface pitting, or worn bore holes, which reduce transmission accuracy and seriously affect ...

Read More »Laser surface heat treatment for stamping, punching, forming, bending and press dies

In sheet metal processing, stamping dies, punching dies, forming dies and bending dies operate under heavy loads, continuous impact and high friction. Without proper heat treatment, these tools wear quickly, suffer from edge chipping, deformation and a rapid reduction in service life. Laser Hardening (Laser heat treatment) is an advanced ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông