Except the Carbide, cobalt alloy, ceramic, self-flux powder, there are several powder we produce is also important to thermal spray industry. these powders are pure Mo powdeloyr, NiAl powder, Ni20Cr powder, Ni coated graphite powder, Titanium powder… Chemistry Grade Flow Density Size Hardness Application Data Other Special powder Mo powder ...

Read More »huongnt

Carbide/WC Powder

Characteristics of Carbide/ Tungsten Carbide powder: Carbide/Tungsten Carbide Powder is known for its wear resistance, adhesion resistance, corrosion resistance, impact resistance, high heat resistance… Apply for different technology: – HVOF / HVAF – Plasma Transfer Arc (PTA) – Laser Cladding Kinds of Carbide/ Tungsten Carbide Powder: – Tungsten Carbide Cobalt ...

Read More »Fe-based Powder

What is stainless steel? Created by the addition of at least 10.5% Chromium (Cr) and Iron (Fe), stainless steel is extremely resistant to corrosion, making it the perfect choice for harsh environments. Characteristics of Fe-based powder (Stainless Steel): Fe-based alloy powder is a material composed mainly of Iron and ...

Read More »Cobalt Based Powder

Characteristics of Cobalt based powder: Cobalt-based alloy powder is a material composed mainly of Cobalt and some other alloys. Cobalt-based alloy powders are known for their excellent corrosion resistance, oxidation resistance and durability. They are often used in high temperature environments due to their superior heat resistance. Apply for different ...

Read More »Nickel Based Powder

What is Nickel? Nickel is one of five metals in the ferromagnetic group, also known as Nickel, with the chemical symbol Ni. Nickel is white-silver in color, usually in the form of compounds. Because in its compound form it is inert to oxygen gas while in its pure form it ...

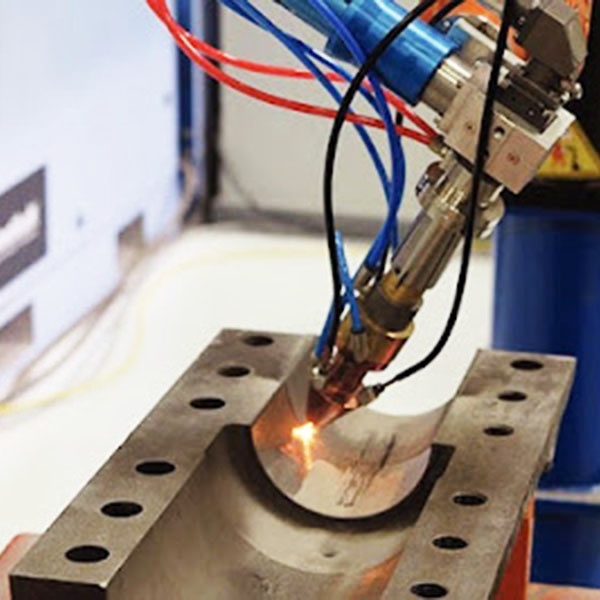

Read More »Laser Cladding System with Closed Chamber

Laser Cladding System with Closed Chamber: Laser Cladding System with Closed Chamber is a laser coating system in closed chamber with equipment mainly including CNC system, working system, laser, powder feeding system, robot control system … The Laser Cladding machine has a full range of functions, diverse performance and strong ...

Read More »Laser Cladding System with Opened Chamber

Laser Cladding System with Opened Chamber: Laser Cladding System with Opened Chamber is a Laser coating system with a customized long working area according to customer requirements from a few meters to tens of meters. The machine can meet the requirements of spray coating application and quick repair of ...

Read More »Turbine

Hydroelectric equipment often works in harsh environments due to extremely high pressure and great friction with water flow, so ordinary metal components cannot guarantee long-term operation, but must use special alloys. It is for this reason that it is extremely difficult to repair equipment such as stoppers, injectors, shafts, ...

Read More »Engine Bearings

For the lining of the sliding faces of hydrodynamic bearings, tin alloys are commonly used. An important criterion for the primer is to be applied free of foreign particles, having a higher hardness than the composition used. These unwanted particles can damage the shaft, the bearing as a whole, and ...

Read More »Drive Rollers

Damage to the drive shaft due to long-term wear is inevitable, but we have a solution to repair it domestically at a much lower cost thanks to modern methods such as Laser Cladding and PTA. . After welding hard alloy, this method also requires special machining solutions to achieve high ...

Read More »

Laser Cladding Phương Đông

Laser Cladding Phương Đông