Aluminum pistons are critical components in engines, operating under high temperatures, continuous friction, and cyclic mechanical loads. Over time, pistons may suffer from surface wear, deep scratches, crown damage, or dimensional deviation, leading to reduced performance and increased maintenance costs.

Laser Cladding – A Precision Refurbishment Solution for Aluminum Pistons

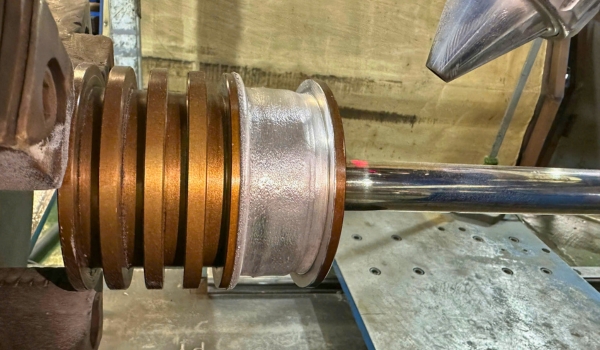

Laser Cladding is an advanced surface engineering technology that uses a high-energy laser beam to deposit aluminum alloy powder onto worn or damaged areas of the piston.

The process is precisely controlled, creating a strong metallurgical bond between the deposited layer and the base material, making it especially suitable for surfaces requiring high dimensional accuracy.

Key Advantages

- Minimal heat-affected zone, reducing component distortion

- High-precision deposition, allowing accurate control of coating thickness

- Strong metallurgical bonding with excellent adhesion

- Material compatibility, using aluminum alloy powders matched to the piston

- Extended service life, reducing replacement and maintenance costs

Post-Processing After Refurbishment

After Laser Cladding, the piston undergoes precision machining and finishing to restore dimensional accuracy, roundness, and surface smoothness, ensuring stable and reliable operational performance.

Phuong Dong – A Pioneer in Laser Cladding in Vietnam

Phuong Dong is a leading and reputable provider of Laser Cladding solutions in Vietnam, certified to ISO 9001:2015.

All processes—from inspection, procedure design, laser cladding, finishing machining to quality control—are standardized to ensure precision, durability, and reliability for every restored component.

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông