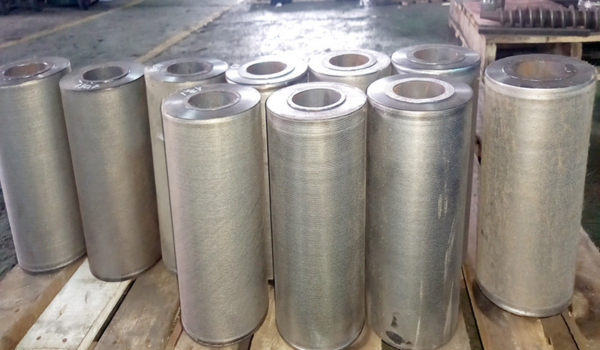

In the steel manufacturing industry, rolling mill rollers are among the most critical components in the production of both cold rolled and hot rolled steel. These rollers are subjected to extreme working conditions — including high temperatures, high pressures, and intense friction — as they continuously come into contact with raw steel sheets and strips. As a result, they are prone to rapid surface wear, cracking, pitting, and deformation, which significantly shortens their operational lifespan.

Traditionally, worn rollers are either replaced entirely or sent abroad for refurbishment — both of which involve high costs and long downtime. However, with modern surface engineering technologies such as Laser Cladding and PTA (Plasma Transferred Arc) coating, manufacturers now have a cost-effective and efficient solution for roller restoration.

✅ Benefits of Using Laser Cladding / PTA for Roller Refurbishment:

-

Significantly Extended Service Life

By applying a hard, wear-resistant coating layer of special metal alloys (such as Stellite, Inconel, or Tungsten Carbide-based materials), the surface of the roller is enhanced to withstand high wear and heat, increasing its durability by up to 10–20 times compared to conventional alloy steel surfaces. -

Reduced Maintenance & Replacement Costs

The longer service life of coated rollers means less frequent replacements, reduced stockpiling of spare parts, and lower maintenance overhead. -

Minimized Downtime

Quick turnaround in local roller restoration, combined with the reduced frequency of failures, leads to less downtime on production lines — a crucial factor in high-volume steel manufacturing. -

Superior Metallurgical Bonding

Laser Cladding and PTA provide metallurgical bonding between the cladding layer and the roller substrate, ensuring high adhesion strength and preventing delamination even under extreme loads. -

Customizable Surface Properties

Depending on the working environment (e.g., dry friction, contact with scale, high-temperature oxidation), specific cladding materials and layer thicknesses can be selected to best match the application. -

Domestic Restoration Advantage

Localized roller refurbishment services with modern cladding equipment help steel plants avoid overseas logistics, long repair cycles, and foreign exchange costs. This brings more than 90% savings in time and expenses compared to importing new rollers or sending them abroad for repair.

???? Applications:

-

Work rollers and backup rollers in hot and cold rolling lines

-

Deflector rollers, tension rollers, guide rollers in steel coil production

-

Rollers used in pickling lines, galvanizing, and color coating lines

-

Any steel processing line where rollers experience high wear or corrosion

At Phuong Dong Industry, we offer comprehensive roller restoration solutions using state-of-the-art Laser Cladding and PTA systems. Our team has experience working with a wide range of roller materials and failure modes, ensuring optimal coating selection and process control.

Whether you are facing issues with surface cracks, pitting, or worn-out rollers, we are here to help you extend the lifespan of your equipment and optimize production performance.

Contact us today for a consultation or quotation:

PHUONG DONG INDUSTRY & TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi, Vietnam

Hotline / Zalo: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông