During operation, the Ø62 mm bore inside the copper pump housing becomes worn due to friction and corrosive fluid contact. Inside the bore are multiple narrow longitudinal grooves, and the geometry is both deep and confined, making conventional repair methods extremely difficult.

Technical Challenges

The restoration of the Ø62 mm bore presents several challenges:

- Narrow space and deep bore – difficult for the welding nozzle to reach the repair area.

- Multiple small internal grooves that must not be welded, as these locations can easily be filled or blocked during conventional welding.

- Copper base material with very high thermal conductivity, which can lead to overheating or deformation when using high-heat welding processes.

These factors require a welding technology with exceptionally high precision.

Phuong Dong’s Solution

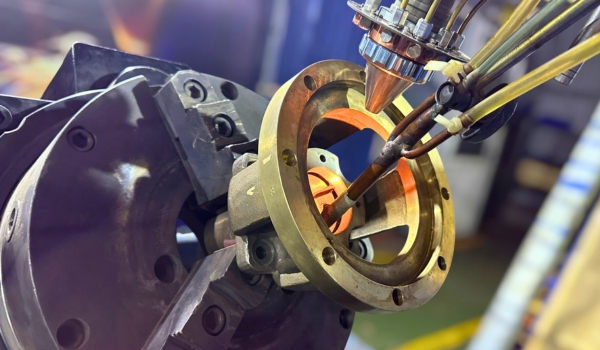

We apply Laser Cladding technology using specialized copper-based powder, fully compatible with the copper substrate and providing excellent metallurgical bonding and durability.

A custom-designed welding nozzle for ultra-small bores is utilized, allowing precise access to the repair area where standard welding nozzles cannot operate.

Combined with Phuong Dong’s proprietary automatic laser ON/OFF control software, the solution ensures:

- Accurate cladding of each localized worn area inside the bore.

- Automatic laser shut-off when passing over internal grooves, preventing any blockage.

- Optimal energy control, minimizing overheating and deformation.

Key Advantages

- Effective restoration of small, deep bores with internal grooves.

- Grooves remain intact—no clogging or overfill.

- Strong metallurgical bonding with high adhesion.

- Minimal heat-affected zone → no distortion.

- More cost-efficient compared to replacing the part.

Restoration Result – Ø62 mm Bore

After laser cladding and precision machining, the Ø62 mm bore fully meets technical specifications, ensuring sealing performance, surface consistency, and geometric accuracy.

The component operates reliably and stably under working conditions after being returned to service.

Phuong Dong – A Pioneer in Laser Cladding in Vietnam

Phuong Dong is a leading and reputable provider of Laser Cladding solutions in Vietnam, certified to ISO 9001:2015.

All processes—from inspection, procedure design, laser cladding, finishing machining to quality control—are standardized to ensure precision, durability, and reliability for every restored component.

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông