In modern manufacturing plants, grinding and surface finishing tasks often require significant time and rely heavily on manual labor, leading to low productivity and inconsistent quality. Robotic grinding technology offers an effective solution by automating the process, enhancing accuracy, and ensuring consistent results across all workpieces.

1. What is a Grinding Robot?

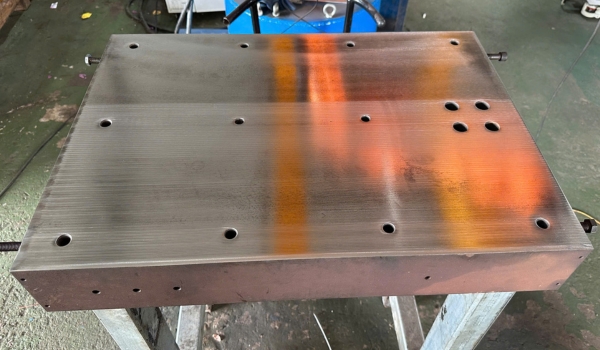

A grinding robot is a system that uses a robotic arm combined with grinding wheels or specialized grinding tools to perform operations such as deburring, surface smoothing, polishing, and finishing workpieces according to technical standards.

2. Key Benefits of Robotic Grinding

- High precision: Stable grinding force ensures uniform surfaces and consistent roughness.

- Increased productivity: Operates continuously 24/7 without limitations from human labor.

- Improved safety: Minimizes direct exposure to grinding dust, sparks, and hazardous environments.

- Consistent quality: Every product achieves the same result, reducing errors and scrap rates.

- Flexibility: Easily programmed to handle various types and sizes of components.

3. Applications of Robotic Grinding

- Surface finishing and treatment of mechanical components.

- Removal of burrs, protrusions, and surface imperfections.

- Polishing and smoothing of metal, stainless steel, and other industrial materials.

- Suitable for production lines requiring high precision and uniform quality.

4. Why Should Businesses Invest in Robotic Grinding?

With the rising cost of labor and increasing demands for high-quality products, robotic grinding helps businesses optimize costs, shorten production time, and improve product quality. This technology is especially suitable for production lines that require long-term stability and high precision.

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo/Whatsapp: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông