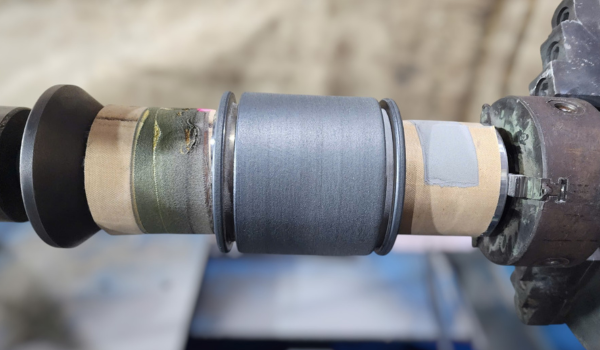

Laser Cladding is an advanced surface restoration and strengthening technology. It utilizes a high-energy, focused laser beam to melt metallic powder and fuse it with the base material surface. This process creates a dense, wear-resistant coating with excellent bonding and mechanical properties. Laser cladding is especially suitable for components subject to heavy wear, corrosion, and high loads — such as piston rods in heavy industries, oil & gas, chemical plants, cement production, and hydropower systems.

Application for Piston Rods

Piston rods typically operate under high pressure and heavy friction, making them prone to wear, cracks, or surface damage. Laser cladding offers an efficient solution for restoring or upgrading piston rod surfaces, with key benefits including:

- Enhanced resistance to wear, corrosion, and heat

- Accurate restoration of dimensions and surface finish

- Extended service life, significantly longer than the original base material

- Reduced replacement costs and minimized downtime

Key Advantages of Laser Cladding

- High precision: Minimal heat-affected zone, no distortion of components

- Strong metallurgical bonding: No peeling or delamination like traditional coatings

- Versatile coating materials: Nickel-based, Cobalt-based, Tungsten Carbide alloys… tailored to your application

- Integrated quality control: Pre- and post-welding inspection ensures technical compliance and durability

Contact PHUONGDONG INDUSTRY today for expert consultation and technical support!

PHUONG DONG INDUSTRIAL AND TRADING CO., LTD

Address: Alley 70, Dan Di, Uy No, Dong Anh, Hanoi

Phone/Zalo: +84 987 822 360

Laser Cladding Phương Đông

Laser Cladding Phương Đông